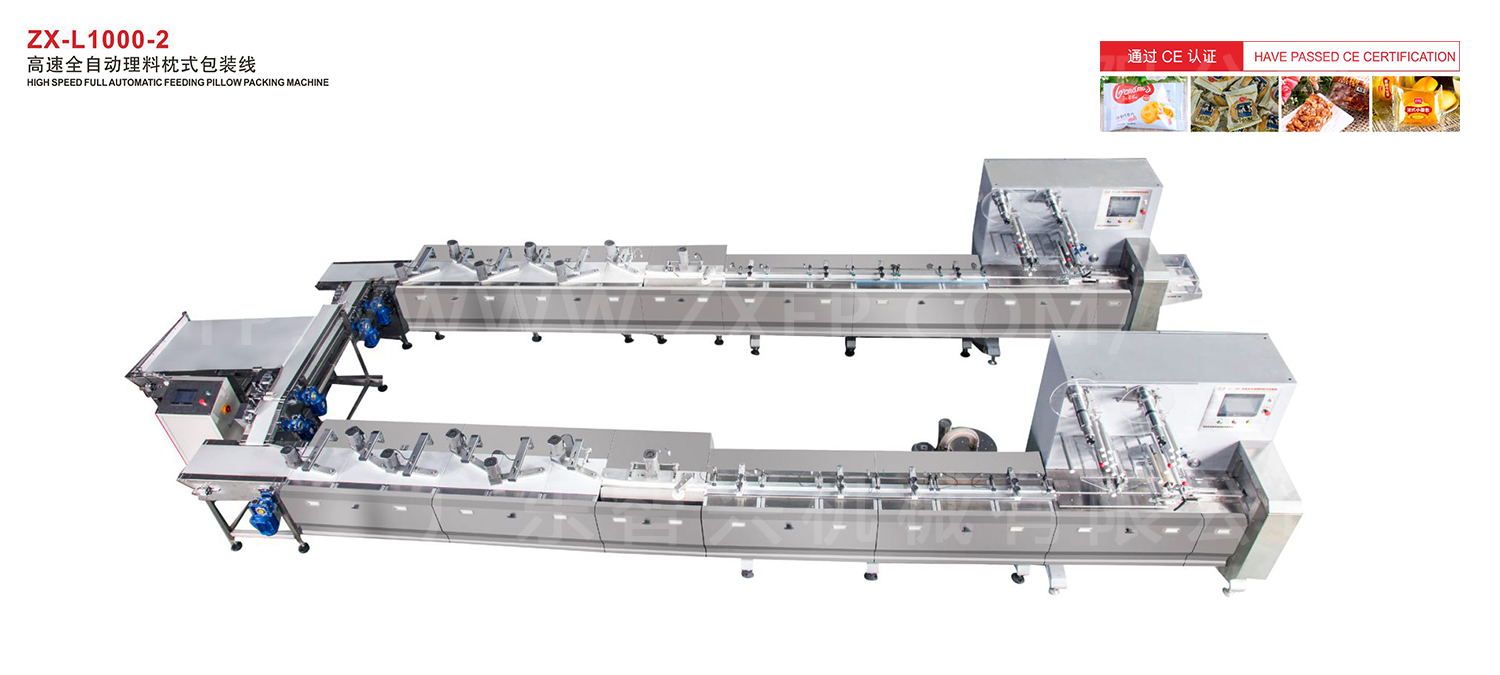

Purpose:

It is applied for the pillow packing of products with easy broken surface,such as chocolate,water,puffing food,rice cake,cake,Swiss roll,caramel treats,nougat,candy floss and other types of candies or enrobing products.

| Performance technical parameters |

| MODEL NO. |

ZX-L1000-2 |

| Packing Speed (grains/minute) |

50~1200 |

| Products Dimenson(mm) |

15-200*15-60*5-30 |

| Total Power(kw) |

9.5 |

| Total Weight(kg) |

3500 |

| Power Source(V Hz) |

380V 50Hz |

Main performance and structural characteristics:

1. Advanced full servo control system and simple transmission construction,low maintenance and low noise;

2. It can be connected directly with the production line and make the products sending,forming,filling and sealing an full automation process.It improves the working efficiency and reduce the cost.

3. The control system adopts high quality electronic parts.With touch screen and friendly machine-human interface,it is easy to operate and you can see the machine working processes clearly.

4. With paper splicer system and it can change the film roller automatically without stop,which improves the working efficiency.

5. The feeding belts don’t need tools to release or install.There is wastage plate under the belts and it is easy for maintenance and clean and it saves time and labor.

6. With product-inspecting system and it helps to achieves the real no-empty package.The packing rate is 100%.